Difference Between Industrial Plastics

All thermoplastic enclosures we stock are manufactured using high-quality, halogen-free, and recyclable polycarbonate or ABS plastic. Although plastic is much lighter than steel, it has very high impact- resistance, in addition, any dents or bumps are not as noticeable in plastic as they would be with steel. Thermoplastic is also easier to machine, maintain, and alter than steel or aluminium enclosures with similar impact and chemical resistances.

Both Polycarbonate and ABS are forms of Thermoplastic, however there are some important differences to remember when purchasing your enclosure. While Fibreglass is not technically a thermoplastic, it is the other major non-metallic enclosure material, so we have included it for the purposes of the following comparison.

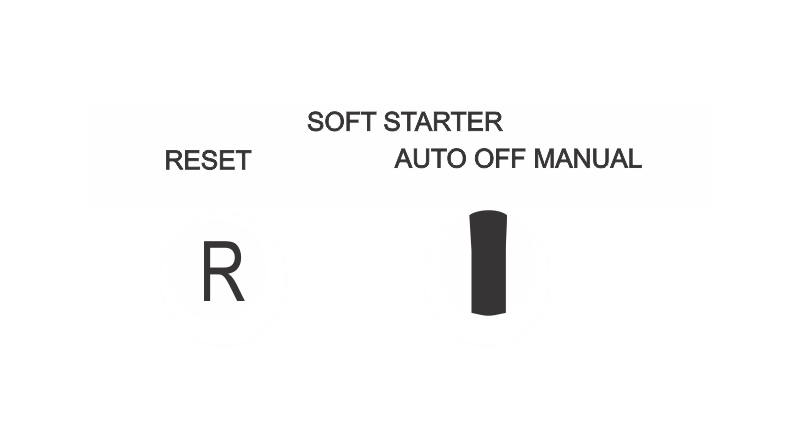

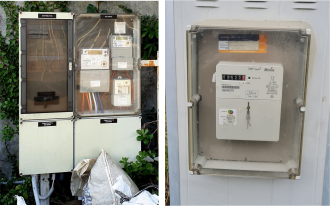

Polycarbonate is an amorphous thermoplastic material whose high heat resistance and excellent physical properties make it an ideal material for enclosures. Polycarbonate can withstand a wide range of temperature fluctuations and its good electrical properties are unaffected by humidity. As a self-extinguishing material, polycarbonate requires no protective coating to prevent fire spreading. Polycarbonate is the most UV stable of all thermoplastics and a high-quality polycarbonate will withstand New Zealand’s levels of UV for many years without showing any signs of deterioration or brittleness. The following images were taken three years after they were installed.

ABS (acrylonitrile-butadiene-styrene) is also an amorphous thermoplastic material with good physical properties and high resistance to chemical attack. It is an ideal cost-effective material as it is easier to injection mould than Polycarbonate. ABS is not as resistant to UV rays as polycarbonate and will discolour and become brittle rapidly if directly exposed to high UV levels. Due to New Zealand’s high level of UV, emf would recommend that Polycarbonate enclosures are used anywhere where there is likely to be regular exposure to direct sunlight. The following images were taken 2-4 years after installation.

Fibreglass is another common enclosure material. In the enclosure market it is often referred to as glass-reinforced plastic (GRP), glass-fibre reinforced plastic (GFRP) or GFK (For trivia purposes this comes from the German name “Glasfaserverstärkter Kunststoff”). In these enclosures the fibres may be randomly arranged, flattened into a sheet, or woven into a fabric before being set in a polymer —most often based on thermosetting polymers such as epoxy, polyester resin, or vinylester. (Ensto’s Cubo O and P Bases and Polyboxes use fibreglass reinforcing in their polycarbonate for strength.) The following images were taken 2-4 years after installation.

While fibreglass is often the cheapest of the three, fibreglass enclosures tend to "bloom" and deteriorate when exposed to UV rays over extended periods. This is due to the resins that the fibreglass is set in isn’t usually UV stable and therefore ‘burns’ off, leaving a fluffy fibreglass exposed which lowers the chemical and impact resistance as well as IP rating. This issue can be resolved by applying a UV protective paint, but this is obviously a more labour-intensive solution and increases the cost. The elasticity of the fibreglass material naturally diminishes over time also causing reduced impact resistance. During modifications, fibreglass can also splinter and produce dust which can lead to respiratory illnesses or at the very least itchy fingers! Fibreglass enclosures are a very cost-effective solution if regular maintenance is completed.